Boiler Installation and Repair in Clio, Michigan

Hydronic Boiler Systems Designed For High Demand And Long Winter Cycles

Boilers rarely draw attention until the heat disappears, pipes cool, and buildings lose their balance. In cold-weather regions, boiler systems are not comfort accessories; they are infrastructure. At Comfort Control Heating and Cooling, boiler installation and repair are treated as precision heating engineering, not routine mechanical work for residential and commercial properties. Every boiler system must deliver consistent heat, operate safely under pressure, and respond predictably to demand changes throughout long winter cycles.

After 25 years in the HVAC trade, we understand that boiler reliability is built through accurate sizing, disciplined installation, and repair decisions grounded in system behavior, not assumptions.

We serve Clio, Michigan as the primary service focus, supported by daily exposure to Genesee County’s winter severity, mixed building stock, and aging mechanical infrastructure. Nearby communities such as Mount Morris, Vienna Township, Flushing, and Birch Run experience similar cold patterns, fuel variations, and seasonal strain on hydronic heating systems. Prolonged freezing temperatures, fluctuating utility conditions, and older pipe networks demand boilers that are configured for resilience, efficiency, and controlled heat distribution rather than generic factory defaults.

Boiler systems demand respect for physics, safety codes, and long-term operating costs. Our team approaches every installation with heat-load accuracy and future serviceability in mind. Repairs concentrate on restoring balance between combustion, circulation, and control systems. Maintenance planning emphasizes predictable performance across years, not just seasonal startup success. This structured approach protects buildings from uneven heating, excessive fuel consumption, and unexpected breakdowns during the coldest periods of the year.

Our Boiler Installation and Repair Services

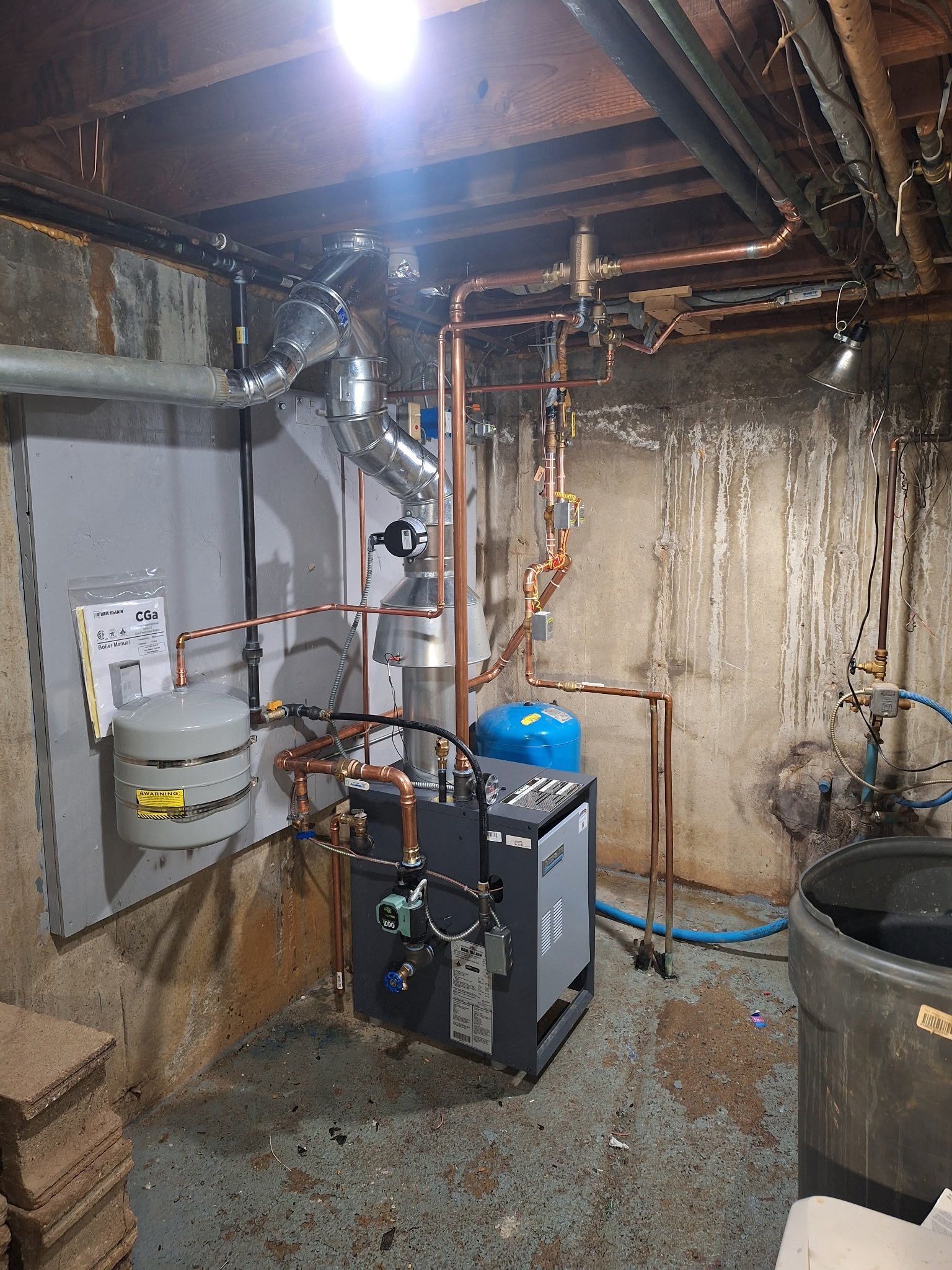

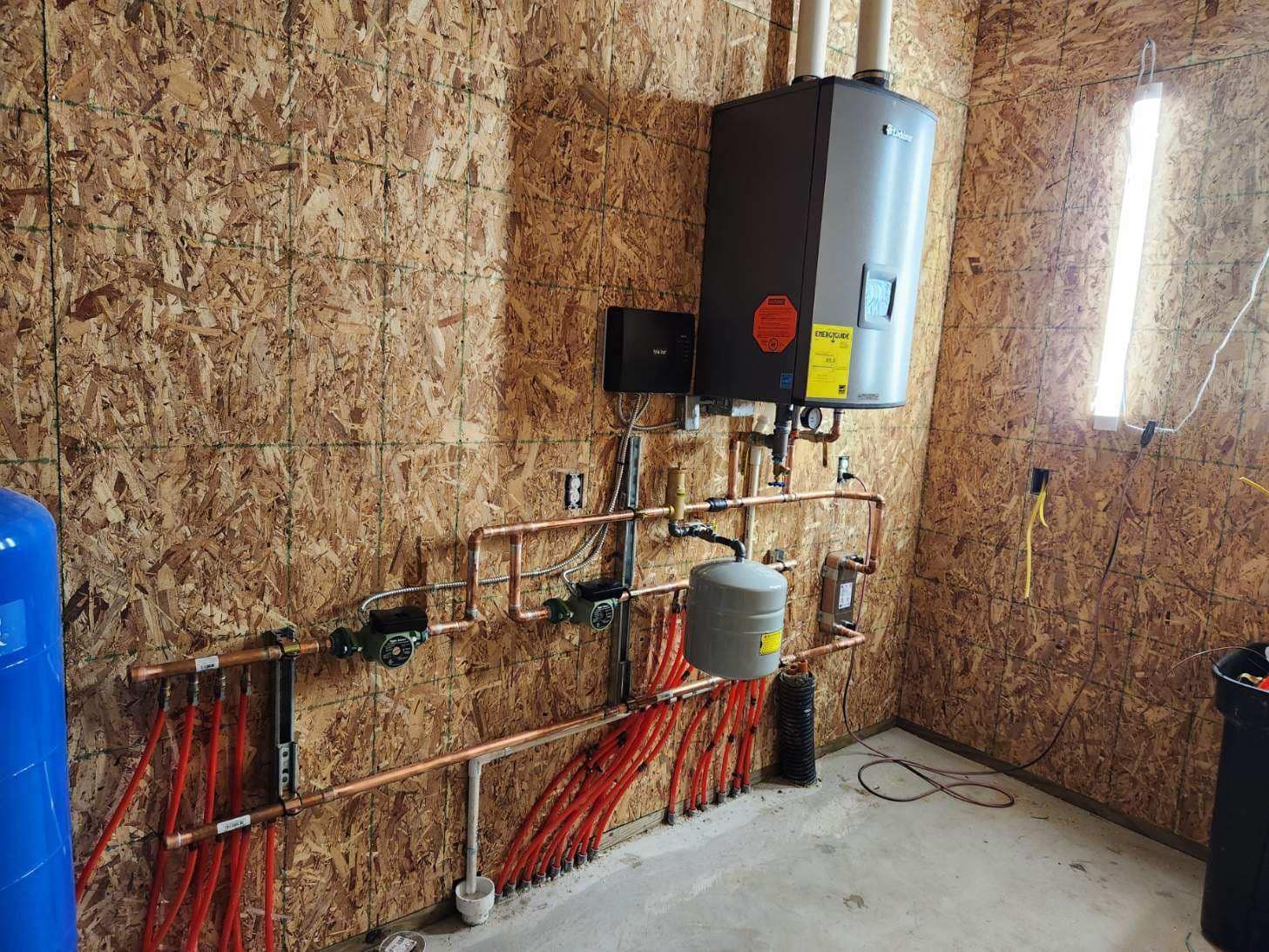

New Boiler Installation

Boiler installations include detailed heat-load analysis, precise equipment selection, piping configuration, venting design, and full system commissioning. Correct installation supports efficient combustion, balanced circulation, and long-term reliability while ensuring boiler capacity aligns accurately with building demands, operating patterns, and future heating requirements without unnecessary oversizing risks.

Boiler Repair and Diagnostics

Boiler repair services focus on identifying root causes such as ignition failures, pressure imbalance, circulation breakdowns, or control malfunctions. Accurate diagnostics enable targeted repairs that restore safe operation, improve efficiency, and prevent recurring failures during critical heating periods when consistent performance is essential.

Boiler Replacement and System Upgrades

Aging boiler systems may require replacement or performance upgrades. Replacement services assess efficiency losses, operating costs, and system compatibility, ensuring new boilers integrate with existing piping while delivering improved reliability, better heat output, and compliance with modern efficiency and safety standards.

Circulator Pump and Zone Valve Service

Hydronic heating performance relies on proper water movement through the system. Servicing circulator pumps and zone valves restores even heat distribution, corrects temperature imbalance, and prevents excessive boiler strain caused by restricted flow, failed components, or improper zoning control within hydronic networks.

Combustion and Venting Inspection

Combustion analysis and venting inspection verify safe fuel burning and proper exhaust removal. Correct adjustments protect efficiency, reduce emissions, and prevent hazardous conditions while ensuring boilers operate within manufacturer specifications and safety code requirements throughout demanding heating seasons.

Preventive Boiler Maintenance

Preventive boiler maintenance includes system cleaning, pressure verification, control calibration, and safety testing. Regular service minimizes fuel waste, extends component lifespan, and keeps boilers operating reliably during peak winter demand without unexpected shutdowns, efficiency loss, or performance degradation over time.

Benefits of Professional Boiler Services

Reliable Cold-Weather Performance

Boilers designed and serviced correctly deliver consistent heat during prolonged freezing conditions. Professional installation and repair prevent uneven temperature zones, pressure instability, and circulation issues, ensuring dependable warmth even during extended cold snaps when heating systems operate continuously under maximum seasonal demand levels.

Improved Fuel Efficiency

Well-tuned boilers consume less fuel while producing steady heat output. Proper combustion adjustment, heat exchanger condition, and circulation balance reduce wasted energy, lower operating costs, and help systems maintain efficiency throughout long heating seasons without excessive cycling, short cycling, or unnecessary thermal losses.

Extended Boiler Lifespan

Boilers last longer when internal stress is properly controlled. Accurate installation, pressure regulation, and timely repairs prevent premature wear on heat exchangers, pumps, valves, and controls, allowing systems to reach or exceed intended service life with fewer major component failures over time.

Safer Heating Operation

Boilers operate under pressure and high temperatures, requiring strict safety oversight. Professional service ensures safety controls, venting, combustion, and fuel delivery function correctly, reducing risks associated with carbon monoxide exposure, overheating, leaks, or pressure-related failures that compromise occupant safety and property integrity.

Consistent Indoor Comfort

Balanced hydronic systems distribute heat evenly across all zones. Correct installation and repair eliminate cold spots, overheating, and delayed response, creating stable indoor environments that remain comfortable regardless of outdoor temperature fluctuations, occupancy changes, or varying building usage patterns throughout the heating season.

Predictable Maintenance Costs

Routine boiler service reduces financial surprises over time. Planned inspections and calibrated adjustments identify developing issues early, allowing maintenance to be scheduled logically instead of reacting to emergency failures that often result in higher repair costs, extended downtime, and unnecessary operational disruption.

Structured Boiler Solutions Delivering Stability Safety And Consistent Heat Performance

Boiler systems succeed or fail long before winter arrives. Their reliability is determined by installation accuracy, repair discipline, and maintenance consistency. In a climate like Clio, Michigan, where cold weather is persistent rather than occasional, boilers must operate as controlled systems, not reactive equipment. At Comfort Control Heating and Cooling, boiler installation and repair are approached with long-term performance as the priority for residential and commercial properties. Every decision is guided by safety, efficiency, and system balance. Installations focus on proper load matching and circulation design.

Repairs eliminate underlying mechanical or hydraulic issues instead of masking symptoms. Maintenance planning anticipates seasonal strain rather than responding after failures occur. This structured methodology protects comfort, controls fuel consumption, and extends system lifespan. When boiler systems are treated as engineered heating solutions, they deliver steady warmth, operational confidence, and dependable performance through even the most demanding Mid-Michigan winters.

Frequently Asked Questions

How do I know if my boiler needs repair?

Common warning signs include uneven heating, unusual noises, pressure loss, rising fuel bills, or frequent cycling. These issues often signal circulation faults, control problems, or combustion inefficiency. Early professional evaluation helps prevent minor defects from escalating into full system failures during severe winter conditions periods.

How long does a boiler installation usually take?

Installation time depends on boiler size, piping complexity, venting configuration, and site conditions. Straightforward replacements may require one or two days, while full upgrades need additional time for piping changes, control integration, testing, and commissioning to confirm safe, efficient, and stable heating operation for buildings.

How often should boilers be serviced?

Annual service is recommended for most boilers, ideally completed before the heating season begins. Older systems or high-use applications may benefit from additional mid-season inspections to maintain safe operation, stable pressure, reliable circulation, and efficient combustion during extended winter demand across residential and commercial properties.

Can boiler repairs improve energy efficiency?

Yes. Correcting combustion imbalance, circulation issues, control calibration, or sensor faults can significantly improve efficiency. Proper repairs reduce fuel waste, stabilize heat output, and prevent boilers from overworking to compensate for unresolved mechanical or hydraulic problems over time that gradually increase operating costs and stress.

When should a boiler be replaced instead of repaired?

Replacement becomes advisable when repair frequency rises, efficiency declines sharply, or critical components fail. In Clio, Michigan, Comfort Control Heating and Cooling evaluates system age, operating costs, safety concerns, and performance trends to determine whether long-term reliability favors continued repair or full boiler replacement planning.

Are boilers suitable for Michigan’s cold winters?

Boilers perform exceptionally well in cold climates when designed, installed, and maintained correctly. Hydronic heating delivers even, steady warmth, tolerates long run times, and maintains comfort more consistently than many forced-air systems during prolonged Michigan winter conditions with fewer temperature swings and reduced distribution losses.

Do boilers require special safety checks?

Yes. Boilers operate under pressure and active combustion, requiring strict safety oversight. Inspections include pressure relief testing, venting evaluation, gas or fuel checks, and control verification, reducing risks related to carbon monoxide exposure, overheating, leaks, or pressure-related failures within occupied residential and commercial buildings spaces.

Do you provide long-term boiler maintenance planning?

Yes. Comfort Control Heating and Cooling in Clio, Michigan provides long-term boiler maintenance planning based on system type, age, and usage intensity. Structured schedules reduce emergency repairs, control lifecycle costs, improve reliability, and help boilers perform consistently throughout demanding winter heating seasons in Mid-Michigan homes.

What our customers have to say...

Testimonials